EK125SM

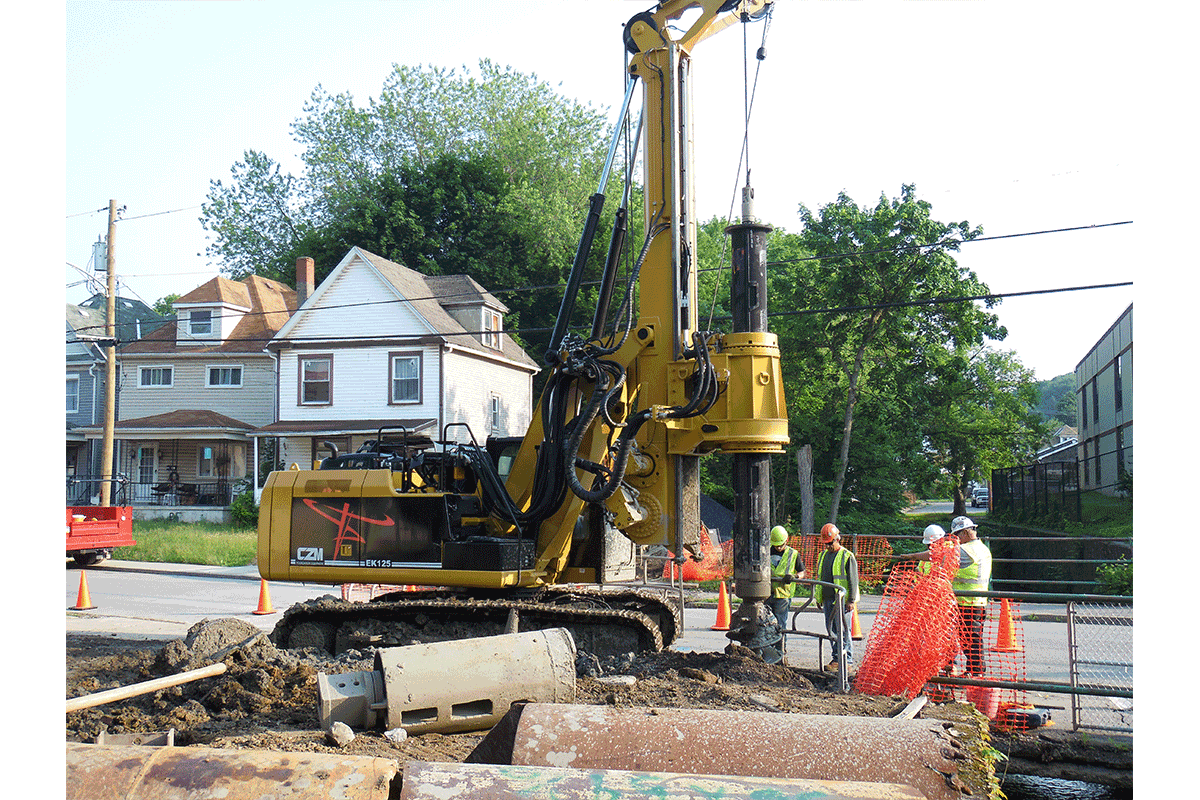

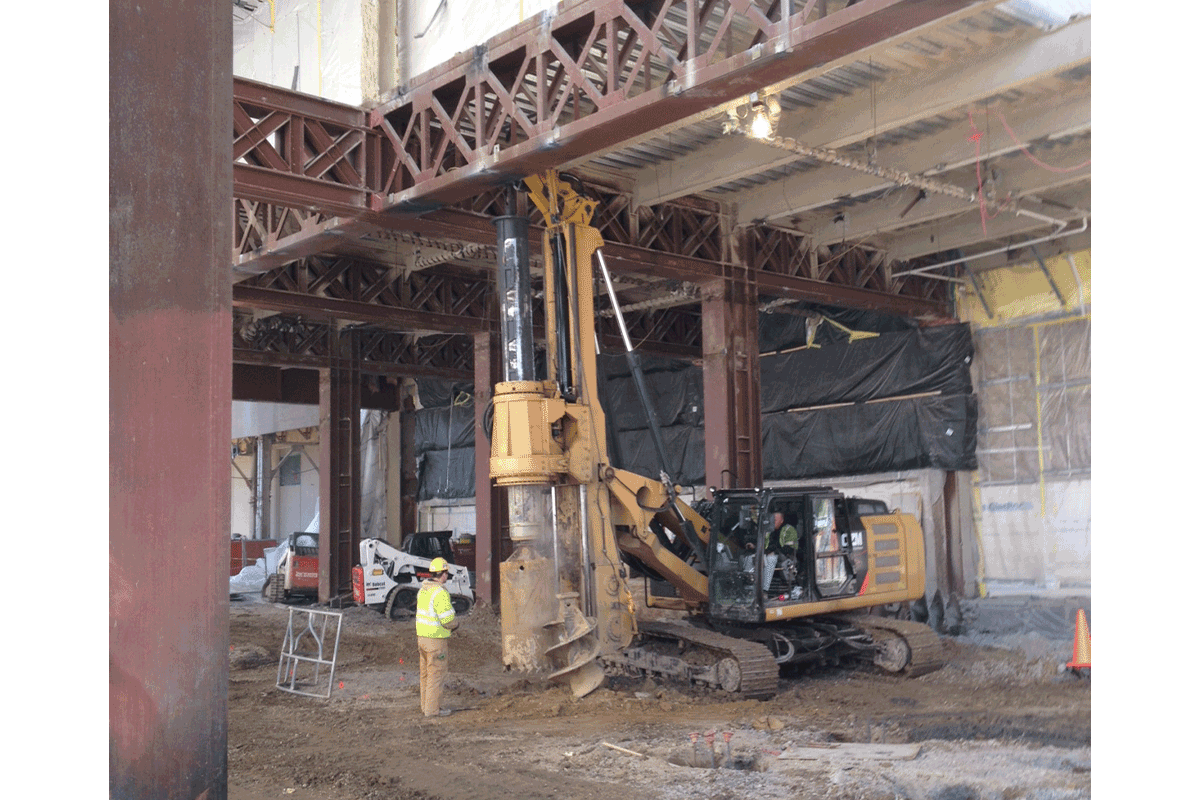

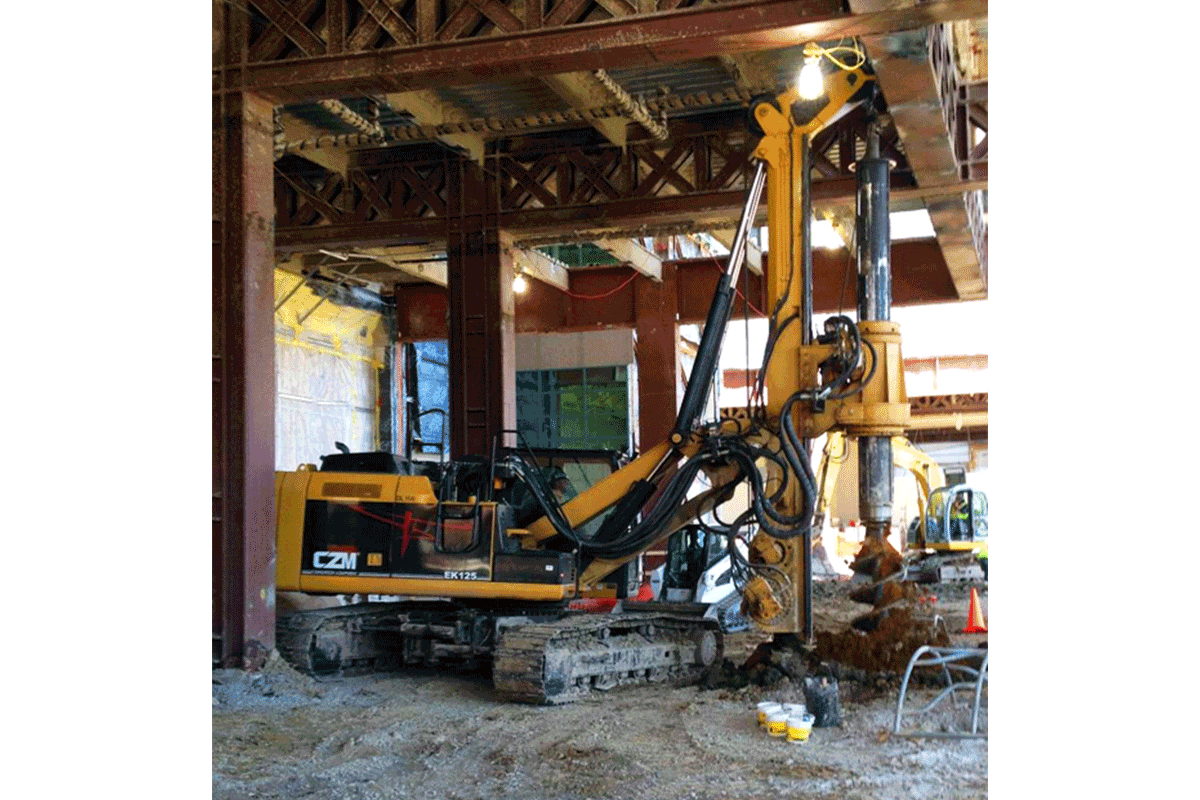

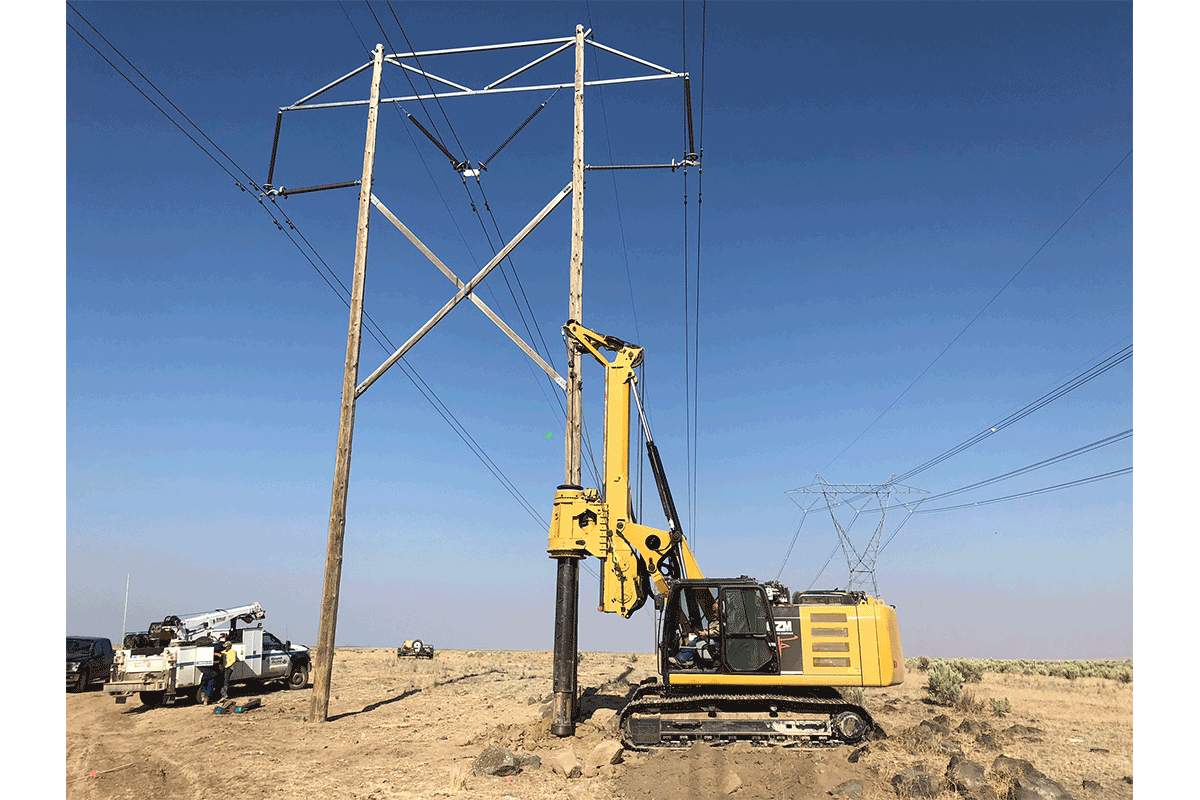

Applications

Kelly Bar

The EK125SM

TECHNICAL SPECIFICATIONS

| Standard Chassis: | CAT 323 Next Gen | |

| Installed Power: | 164 hp | 122 kW |

| Maximum Torque: | 101,700 ft.lbs | 14,000 kg.m |

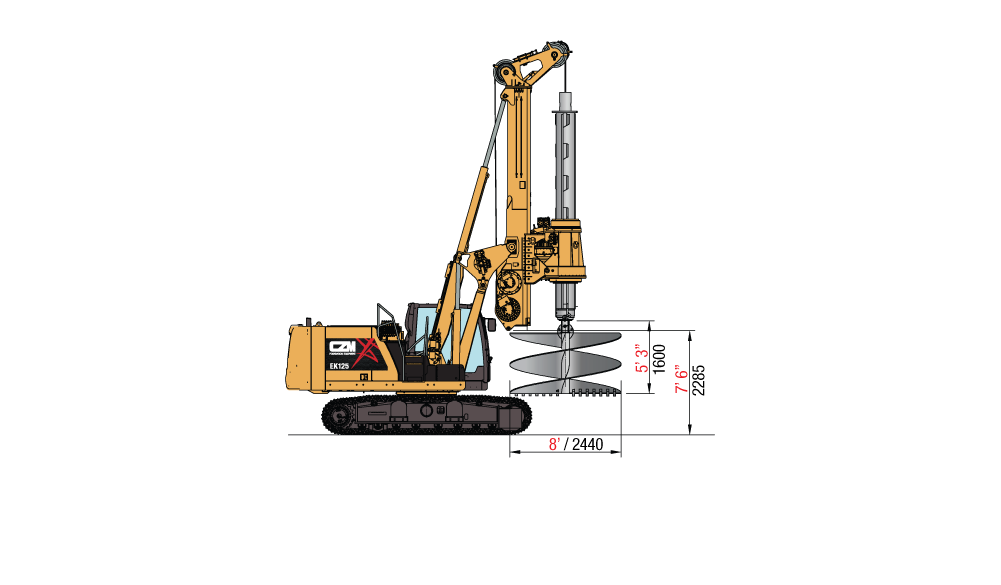

| Maximum Diameter | 8 ft | 2,440 mm |

| Standard Drilling Depth: | 55 ft | 16,700 mm |

| Crowd Force: | 43,000 lbf | 19,000 kgf |

| Crowd Cylinder Stroke: | 9 ft | 2,750 mm |

| Main Winch Line Pull | 41,000 lbf | 18,600 kgf |

| Operation/Transport Weight | 74,500 lbf | 33,850 kgf |

Learn More

About the EK125SM

The EK125SM is a cylinder crowd drilling rig mounted on a CAT323. It is a very popular model for several applications such as foundations, powerlines, utilities, landfill and Rathole. It can be easily converted from Long Mast to Short Mast. It is a one load machine, with easy set up, completely self erecting.

Base:

- The new Cat 323 Next Gen powered by a fuel efficient Tier 4 Final C7.1 ACERT engine.

- Equipped with CAT Vision Link that allows management to monitor machine operations and maintenance data online

Undercarriage:

- Caterpillar variable undercarriage VH4830/3675/600. Reinforced frame H style variable undercarriage.

Mast:

- Reinforced mast, with high resistance steel Weldox 700.

Main Winch:

- Special groove for better cable winding and longer cable life.

- Press-roller included

- 2 gears allows for both high speed and high pulling force.

- Automatic gear shifting, for seamless operation, high production.

- Automatic down the hole winch stop.

- Free willing winch during crowd operation.

- Hydraulic and mechanic brake.

- Hydraulic measurement of pulling force displayed in the cabin.

Rotary:

- Robust design, with 2 slewing bearings on top and bottom, robust pinion and main gear.

- 1 group of Hydraulic Motor / Planetary Gears for high torque and long life.

- Anti-cavitation, anti-shock and cooling system for longer hydraulic motor life.

- Power-shift for High spin-off speed (120rpm) for quick discharge of soil.

- 3 operation speeds and 3 spinoff speeds. For high torque and high speeds.

- Automatic gear shifting, for seamless operation, high production.

- Exchangeable keys, bolted. No need to rebuild keys by welding inside the rotary.

- Hydraulic measurement of torque displayed in the cabin for the operator.

Cab:

- AM/FM Radio, Air conditioning/Heating

- ROPS cab & Top protection

- LCD monitor for Engine and Hydraulics computer, with diagnostic system

- CZM Canbus System for Drilling Monitoring with auto functions.

EK125SM

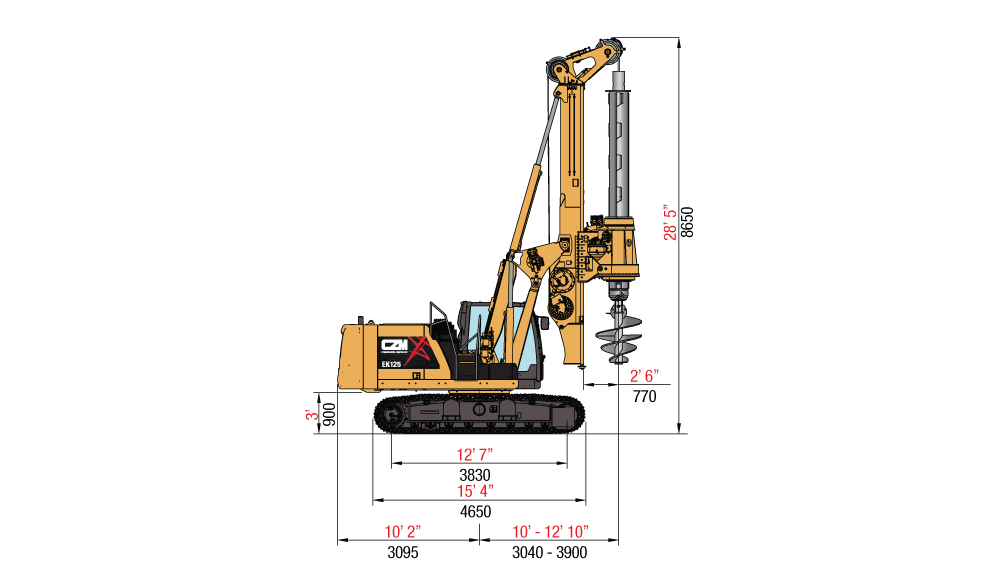

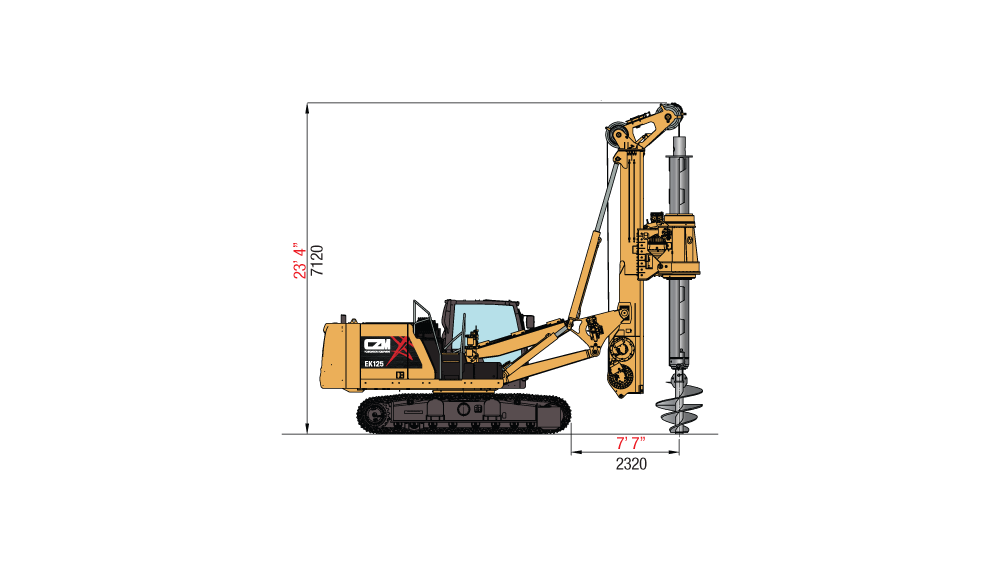

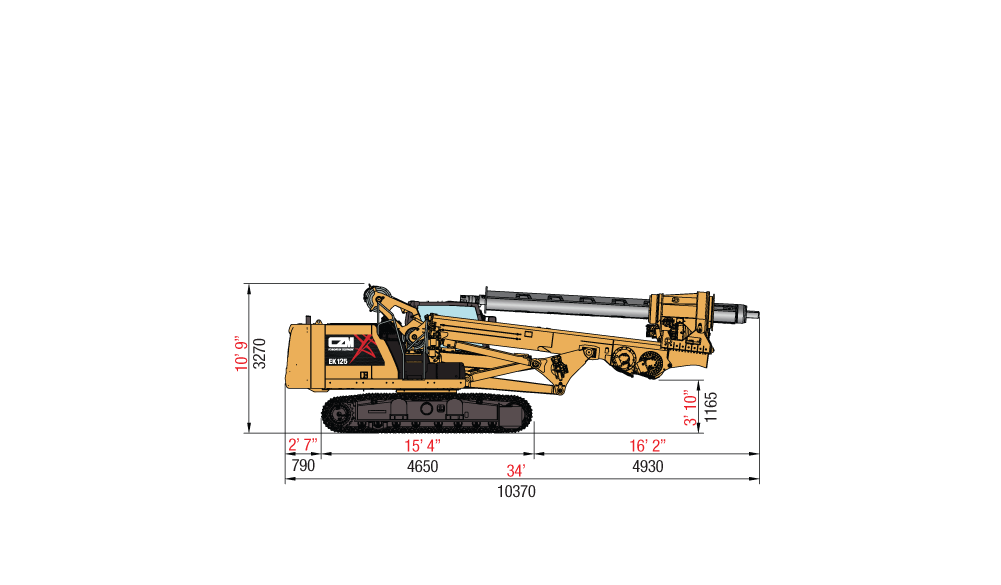

Technical Drawings